Since 2002 Precision Shaper Systems provide robust, reliable and powerful machines trusted by business owners, artisans and craftsmen worldwide.

Board Shaping CNC Systems

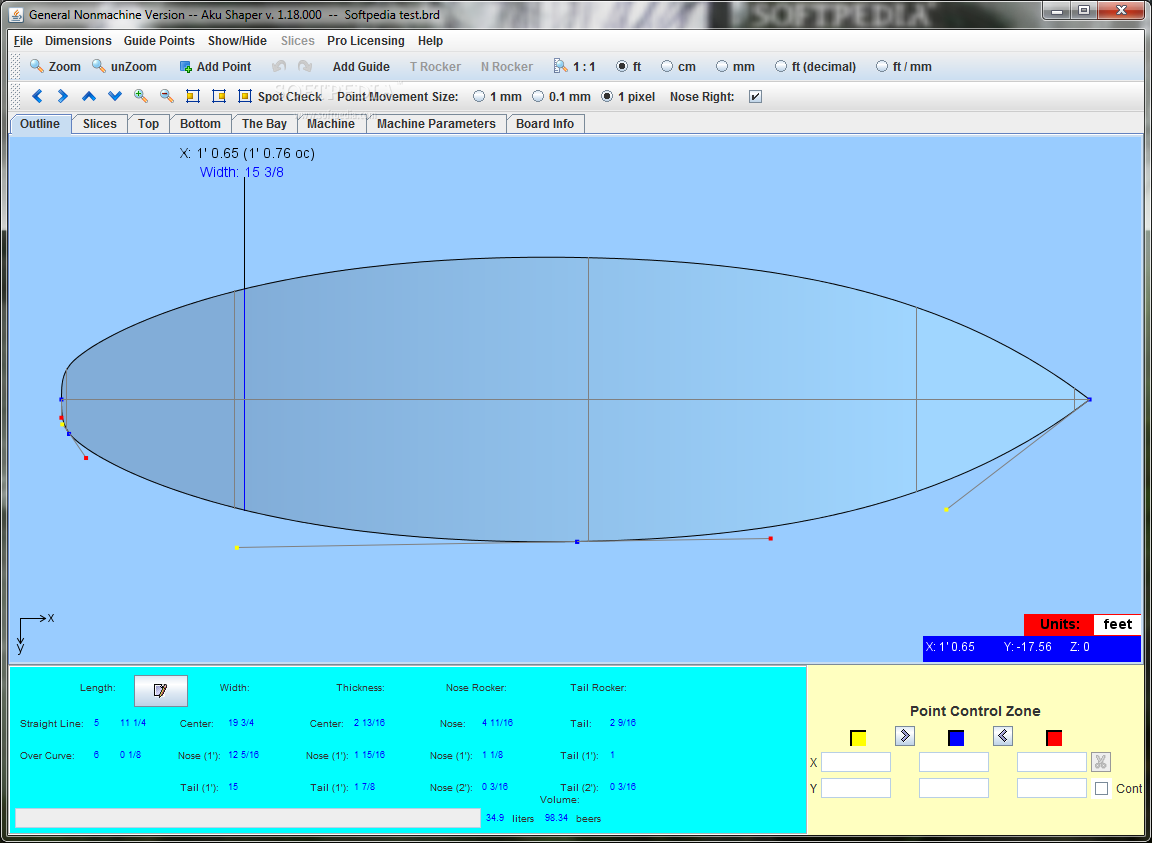

Aku Shaper is a practical and intuitive software solution geared towards users who need to design their own surfboard, based on specific width, thickness, length and curve dimensions. The AkuShaper system was created to preserve the art of the custom surfboard. It is designed to help shapers keep their direct relationship with surfers and protect surfing from the loss of personalization we’ve seen in other sports. Designed and Built by Mike Rickard in Australia. The AkuShaper machine is available in multiple lengths.

Multiple system configurations based on a homogenous platform has allowed our machines to be the trusted global work horses for discerning artisans, craftsmen and board sport designers/engineers.

CNC Table Systems

Our table style CNC machines have proven simple to use, robust and dependable serving the wood, polymer, foam and metal industries.

Bot CNC Machines

Precision Shaper table top systems are used by innovative companies, academic, research institutions and makers. More reliable, powerful and designed for heavy use and abuse in a small package.

- Career

Assessment - Career

Exploration - Education &

Training - Financial

Aid - Job

Strategies - Resources

| User Survey · Contact Us Wednesday, August 11, 2021 |

Aku Shaper How To Make Square Tail

Reshaping the Surfboard Businessby Linda Dela CruzWhat happens when you go on vacation to surf in Australia and some folks ask if you can help create something that’s better than what’s already out there? If you are Jimmy Freese, you end up combining your computer programming skills with your passion for surfing to create a full-fledged business of your own. That fateful day during a surf vacation was in 2001, and three years later Aku Shaper machines were born. The Aku Shaper is a machine that shapes surf-boards in an efficient manner so there’s more time spent out on the ocean in the waves than in shaping the board. “Or you could use the time to shape more boards and make more money,” explains Freese. His Aku Shaper machines have been selling since 2004, and they are in places such as Japan, England, Peru, Tahiti, Australia, New Zealand, California, North Carolina and Hawaii. “Everyone likes the cutter concept, and they get really excited,” says Freese, noting that almost all of his surfboards were made with the cutter. “It uses a circle cutter the size of a dinner plate and about 12 millimeters thick. And the machine spins in both directions.” Once the machine is done with the board, putting on the finishing touches is all that is left. The company’s YouTube video shows that a board can be cut in about 18 minutes.

Freese says one of the challenges is getting the word out about what the machine can do. Some ways have included word of mouth, attending trade shows and getting publicity, such as the Aku Shaper’s recent feature in the February 2009 edition of Surfer Magazine. “Surfing is a small industry, so you kind of know everyone,” says Freese, a Kailua resident and Punahou graduate who has been surfing since he was a child. “Once shapers understand that you can make more boards in a shorter amount of time, they’re interested.” The Aku Shaper business is a three-way partnership that uses the computer programming skills of Freese’s father, Ralph, a math professor at the University of Hawaii at Manoa, and engineer Mike Richard, who specializes in manufacturing machines for the automotive and pharmaceutical industries. The company’s future includes other related products they are developing with the software. Chemical engineer, computer programmer and surfer, Jimmy brings a variety of expertise to the development of the machine and computer technology. With an undergraduate degree in chemical engineering from Carnegie Mellon University, and a Master’s degree in Chemical Engineering from the University of Texas at Austin in the area of Process Control. Jimmy has extensive knowledge about surfboard materials, manufacture and construction, hydrodynamic forces and computer modeling. He spends many hours debugging the software, from both code bugs and usability bugs along with finding the perfect fit between the software, the cutting machine capability and design from a shaper’s perspective. Ralph Freese has been a professor in Mathematics at the University of Hawaii at Manoa for over 30 years. He is extremely respected in his field, Lattice Theory. He also harbors world class computer programming skills. He has solved several long-outstanding problems, including one of importance to computer theory. He is routinely invited to give addresses at international conferences. He was recently awarded The Regents’ Medal for Excellence in Research, a very prestigious award. He holds an undergraduate degree from the University of California at Santa Barbara and a doctorate from The California Institute of Technology.

Mike Richard has had a lifelong passion for automation in the manufacturing industry. He has tertiary qualifications in industrial electronics, engineering and mechanical design, microprocessor based software programming, CAD CAM systems and fifteen years experience as owner/managing director of a successful engineering company which designs and manufactures complex automated machines for both the pharmaceutical and automotive industries. This company has clients throughout Australia and overseas, including Robert Bosch, Siemens, Toyota, Ford, GMH, Astra Zeneca, Pfizer and ITW. Quickbooks validation code in registry. In 2001, Mike restructured the management of this Melbourne-based business and established a new company to design and manufacture shaping machines for the shaping industry. This Gold Coast based company has successfully designed and manufactured over 30 APS3000 and Aku Shaper shaping machines for local and overseas shapers. Mike’s company is now working with the APS3000 software developers, Jimmy and Ralph Freese to build a superior steel-framed shaping machine with a world class controller system to provide shapers with a even more reliable and accurate system. The Aku Shaper is a new design with patent applications for Australia, the US and Europe. With over six years experience in designing and manufacturing a variety of shaping systems, Mike has a unique and detailed knowledge of these systems. He has also completed many machine installations and provided technical support on site or by phone to customers around the world. As a surfer, Mike has a keen interest in continuing to improve and develop the Aku Shaper and he is now happily relocated on the Gold Coast with his wife and three children. 05.29.09 |